High Strength Bolts

High-Strength Bolts: The Backbone of Industrial Reliability

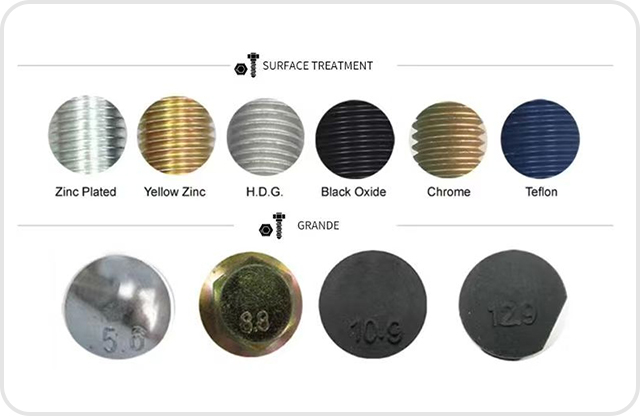

Designed for heavy-duty applications requiring exceptional tensile strength and resistance to shear, vibration, and corrosion.

Compliant with ASTM A325, A490, ISO 898-1, and other global standards.

Materials: Carbon Steel, Alloy Steel, Stainless Steel (A2/A4), and custom coatings (e.g., galvanized, Xylan).

Customizable dimensions, threads, and head styles (hex, flange, countersunk).

Applications of Our Bolts

Construction

Essential for structural connections in skyscrapers, bridges, and pre-fabricated buildings, ensuring high load-bearing capacity and long-term durability.

Oil & Gas

Designed for high-pressure environments, securing pipeline flanges, valve assemblies, and offshore drilling rigs with corrosion-resistant coatings.

Shipbuilding

Marine-grade bolts provide strong fastening for hulls, engines, and deck machinery, offering excellent resistance to saltwater and harsh weather.

Power Generation

Used in turbines, transmission towers, and substation equipment to maintain stability and performance in critical energy infrastructure.

Heavy Machinery

Engineered for extreme loads in excavators, cranes, and mining equipment, ensuring high strength and resistance to impact and vibration.

Why Choose TopBolt High-Strength Bolts?

At TopBolt, we understand that customers require high-strength bolts that deliver outstanding performance, reliability, and value. Our bolts are designed to meet these demands with precision engineering and strict quality control. Here’s what sets us apart:

ISO9001:2015 Certification

Our manufacturing processes are certified to ISO9001:2015, ensuring strict quality control at every production stage. This certification guarantees that our bolts meet international standards for strength, durability, and consistency, providing confidence in their performance across industries such as construction, oil & gas, shipbuilding, and heavy machinery. Every batch undergoes rigorous tensile strength, hardness, and corrosion resistance testing to ensure reliability in even the most demanding environments.

Fast Delivery Time

We prioritize efficiency without compromising on quality. With a high-capacity production facility and optimized logistics, we ensure that orders are processed swiftly and delivered on time. Our monthly output of 2,000 tons enables us to fulfill bulk orders while maintaining rapid turnaround times. Whether you need standard or customized bolts, our streamlined operations and global distribution network ensure that you get the products you need, exactly when you need them.

Customizable Products

Every project has unique fastening requirements, and we provide a wide range of customization options to meet them. From sizes (M4–M100, 3/8"–4") and thread types (full or half-thread) to head styles (hex, square, round) and coatings (galvanized, Xylan®, black oxide, etc.), we can produce bolts that perfectly match your specifications. Whether you require high-strength A325/A490 heavy hex bolts or specialty coatings for extreme environments, our engineering team works closely with you to ensure a perfect fit.

Competitive Pricing

We leverage efficient production techniques and cost-effective sourcing to offer our customers highly competitive pricing. By operating at scale and optimizing raw material procurement, we provide top-tier high-strength bolts at lower costs than many competitors. Whether you're purchasing in bulk for large infrastructure projects or sourcing specialty bolts for critical applications, our pricing ensures that you receive exceptional value without sacrificing quality, strength, or compliance.

FAQs

Q: What distinguishes Grade 8 bolts from ASTM A325?

A: Grade 8 bolts (SAE) are for general machinery, while ASTM A325 is heat-treated for structural steel connections.

Q: Can you supply bolts for subsea applications?

A: Yes, we offer titanium or super duplex stainless steel bolts with NACE MR0175 compliance.

Q: How do I prevent hydrogen embrittlement in high-strength bolts?

A: Our baking process post-coating eliminates trapped hydrogen, ensuring long-term integrity.

Related Blogs

-

The company products consists of bolts & nuts assembled or separate, self tapping or drilling screws, lag screws, threaded rod or studs, washers, which are made from both carbon steel and stainless steel. The products are exported to North America, Europe, Australia, Russia, Southeast Asia and middlIndustries

The company products consists of bolts & nuts assembled or separate, self tapping or drilling screws, lag screws, threaded rod or studs, washers, which are made from both carbon steel and stainless steel. The products are exported to North America, Europe, Australia, Russia, Southeast Asia and middlIndustries -

The company products consists of bolts & nuts assembled or separate, self tapping or drilling screws, lag screws, threaded rod or studs, washers, which are made from both carbon steel and stainless steel. The products are exported to North America, Europe, Australia, Russia, Southeast Asia and middlIndustries

The company products consists of bolts & nuts assembled or separate, self tapping or drilling screws, lag screws, threaded rod or studs, washers, which are made from both carbon steel and stainless steel. The products are exported to North America, Europe, Australia, Russia, Southeast Asia and middlIndustries -

The company products consists of bolts & nuts assembled or separate, self tapping or drilling screws, lag screws, threaded rod or studs, washers, which are made from both carbon steel and stainless steel. The products are exported to North America, Europe, Australia, Russia, Southeast Asia and middlIndustries

The company products consists of bolts & nuts assembled or separate, self tapping or drilling screws, lag screws, threaded rod or studs, washers, which are made from both carbon steel and stainless steel. The products are exported to North America, Europe, Australia, Russia, Southeast Asia and middlIndustries

Contact Us

Thank you very much for your interest in us! If you want to contact us, you can contact us through the following methods:

Mob

+86-18069043038

sales2@topboltmfg.com

Add:

Yuyan, Xiepu Chemical Industrial Zone, Zhenhai District, Ningbo, China